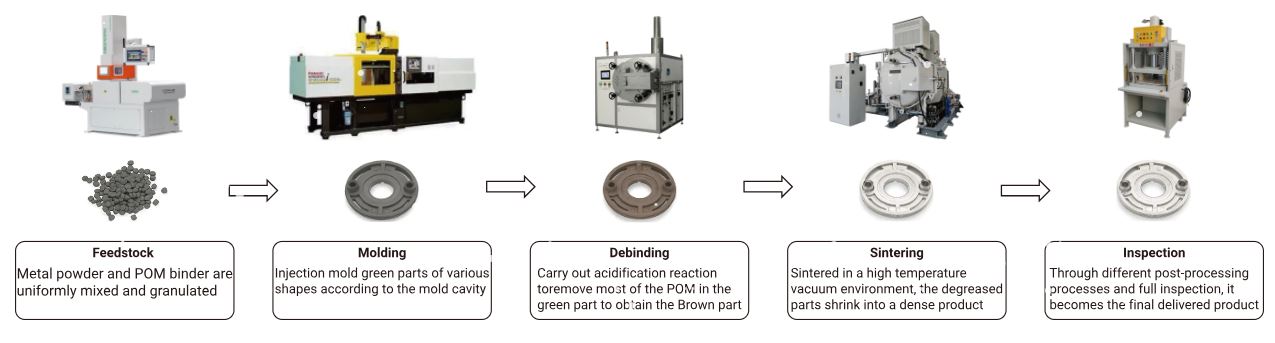

Reasons to Choose Metal Injection Molding Technique

If you are running a manufacturing business for small and complex products, Metal Injection Molding Company can offer you with a reliable solution. Metal injection molding is certainly the key to the future for answering complex manufacturing components.

It is a combination of plastic and Mould Steel Material to create the metal component. This blog points out the reasons to opt for metal injection molding process:

More Similarities to The Final Product

For complex features and minute details, manufacturers often opt for secondary machining. However, it can be obtained from metal injection molding process with advance operations. In fact, features like Knurling, Treads, Calligraphy and complex profiling can be easily achieved in MIM for the mold directly.

Superpower to Design and Manufacturing

MIM process allow to mold the near-net-shape in which manufacturing does not require secondary operations. It is typically fair way to manufacture complex components as the basic shape with feature can be molded with lower cycle. This technology uses multi-cavity. You can achieve tight tolerance in mental injection molding process.

Easy Integration

Typically, metal processing requires manufacturing the parts separately and combining it through welding or press-fitting operation for the design constrains. In fact, the conventional method includes lots of material, energy waste – but, the MIM allows molding the near-net-shape of the part with all desired intricate features including slots, 3D profile and angular holes.

Cost-Effective

MIM process does not have any comparison when it comes to manufacturing. It can produce small, highly complex and intricate parts with profiles that are cost-effective with conventional technique.

Precision Manufacturing

MIM results in eliminating process steps, reducing the product cost and making it feasible to manufacturing complex parts in high volume without additional machinery and investment. You can easily achieve consistent size and shape.

Wide and Efficient Material

The range of material can be processed in MIM is wide and effective. It could be anything from stainless steel to high-speed steel, copper alloys are more. In fact, special rare metal and other types of high temperature alloys can also be used. However, it has certain limitation when it comes to low melting alloy like Zinc and Aluminum.

Wrapping Up

You have all the reasons to choose Metal Injection Molding technique for manufacturing. Choose a reputed company for efficient production unit.